-

6x12-3m PVC Outdoor Large Garage Fireproof Storage Tent

6x12-3m PVC Outdoor Large Garage Fireproof Storage TentWarehouse Tent

-

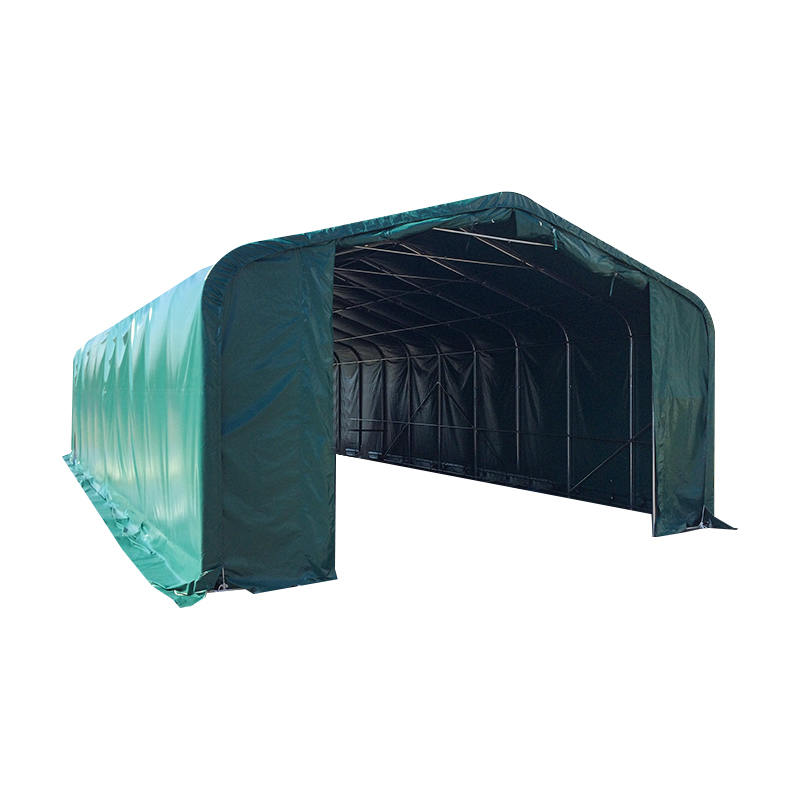

8X12m-3m PVC Warehouse Industrial Large Green Storage Tent

8X12m-3m PVC Warehouse Industrial Large Green Storage TentWarehouse Tent

-

10X12m-3m PVC Heavy Duty Green Warehouse Storage Tent

10X12m-3m PVC Heavy Duty Green Warehouse Storage TentWarehouse Tent

-

9x12mx4.5 Arched Storage Tent, Round-Arched Tent Hall

9x12mx4.5 Arched Storage Tent, Round-Arched Tent HallWarehouse Tent

-

9x12m Arrow Arched Storage Tent, Semicircular Tent hall

9x12m Arrow Arched Storage Tent, Semicircular Tent hallWarehouse Tent

Warehouse Tent Manufacturers

Products & Solutions

CONTACT US

-

+86 15695147631

-

-

No.9 Kangmin Road, Automobile industry Park, Yizheng City, Jiangsu Province, China

Warehouse tents and hoop buildings are one option to consider due to a number of different advantages over conventional storage buildings. These are metal framed structures which utilize a fabric cover tensioned tightly to the frame via ratchets and nylon strapping which can be erected on concrete pads, asphalt, gravel, dirt, and block walls. The temporary nature of warehouse tents and structures allows them to typically be built without the need for building permits. Compare with the ever increasing cost of wood and metal products, the lower cost warehouse storage is a ideal alternative to store parts, vehicles, equipment, and bulk materials.

1. COST

Temporary warehouse tents are a budget-friendly alternative that deliver the enclosed and secured space your facility needs without the expense of a permanent warehouse, which may go unused during the slow season.

2. FLEXIBILITY

Warehouse tents are with clear span structures can be constructed on any terrain to quickly meet your facility’s space needs.

Temporary warehouse structures come in all sizes. As small as 16 square meter to as large as 500 square meter. Plus, temporary structures can be moved when needed, allowing facilities to take advantage of new opportunities immediately.

3. SECURITY

Temporary tents deliver the same level of security as a permanent structure, providing the protection required for sensitive inventory and equipment.

4. ON-SITE STORAGE

Storing excess inventory and equipment in an off-site permanent structure poses disadvantages to business operation. Travel time, waiting on delivery, coordinating access – these obstacles are eliminated when storage is accommodated on-site by using a warehouse tent.

Temporary warehouse structures eliminate the need for off-site storage, allowing you to house all equipment and materials on the same property. Eliminate the excess time and expense incurred with off-site storage when you have a temporary storage solution erected on the same site.

5. DURABILITY

Clear span structures are great for long-term installation because of their durability. These structures are manufactured to withstand heavy winds.

-

In the immediate aftermath of a natural disaster or humanitarian crisis, the first 60 minutes—often called the "Golden Hour"—are critical for establishing medical and logistical hubs. The Rapid Inflatable Relief Emergency Tent is engineered specifically for these high-pressure s...

READ MORE -

In the world of temporary structures, the Inflatable Tent represents a paradigm shift in deployment speed and structural resilience. By replacing traditional heavy metal or fiberglass poles with high-pressure "AirBeams," these structures can be erected in a fraction of the time ...

READ MORE -

For commercial growers and serious horticulturists, the decision to invest in a Greenhouse or a Polytunnel is a pivotal choice that dictates the operational success of a farm. While both structures aim to extend the growing season and protect crops from the elements, they utiliz...

READ MORE

1. Warehouse Tents primarily offer temporary large-scale storage. Compared to traditional fixed warehouses, what unique advantages do they offer in scenarios such as logistics transit, temporary cargo storage, and emergency warehousing, making them a better fit for warehousing needs?

Compared to traditional fixed warehouses, the core advantages of Warehouse Tents lie in spatial flexibility, deployment efficiency, and cost control. In logistics transit scenarios, cargo throughput fluctuates seasonally or with orders. Warehouse Tents can quickly expand or reduce storage space based on demand, avoiding the "idle waste" or "space shortage" issues of traditional warehouses. They can also be flexibly located in open spaces in logistics parks, close to loading and unloading areas, reducing cargo handling distances. For temporary storage of goods (such as factory overproduction and exhibition exhibit storage), there's no need to lease fixed warehouses long-term; warehouse tents can be set up for short periods of time, reducing storage costs. For emergency storage (such as post-natural disaster supplies storage and the turnover of sudden orders), warehouse tents can be quickly constructed in 1-2 days, significantly faster than traditional warehouses. They can also be relocated to meet dynamic storage needs in emergencies. Furthermore, their construction eliminates the need for complex approval processes, significantly shortening the time between demand and use. These advantages are difficult to replicate with traditional fixed warehouses.

2.Warehouse tents need to accommodate large quantities of goods (such as cartons, pallets, and large equipment). What characteristics of their spatial design and load-bearing capacity are required to ensure storage efficiency and cargo safety?

To meet the demands of large-scale storage, warehouse tents must optimize both spatial planning and structural load-bearing capacity. The design utilizes a large-span, column-free structure with spans of 10-30 meters. The structure is free of dense columns, facilitating the access of forklifts, pallet trucks, and other storage equipment, improving cargo handling efficiency. Furthermore, storage areas can be divided by cargo type, such as pallet stacking, bulk cargo, and large equipment, using removable partitions to create flexible separations and prevent mixing of goods. Some designs can also feature a double-tiered storage structure, utilizing the upper level for lightweight shelving to store small items, maximizing vertical space utilization. In terms of load-bearing capacity, the frame must be constructed of high-strength steel (such as Q235 galvanized steel pipe), and the main frame must be rated for a load of ≥ 50 kg per square meter to ensure structural stability when upper shelves or heavy cargo are stacked. The floor must be covered with wear-resistant, waterproof mats or steel plates to enhance its load-bearing capacity and prevent floor indentations caused by the weight of cargo. The roof must be able to withstand additional weight, such as accumulated snow and dust, to prevent structural damage caused by excessive top loads, thus comprehensively ensuring storage efficiency and cargo safety.

3.Different types of cargo (such as moisture-resistant electronic components, weather-sensitive textiles, and large, heavy equipment) have significantly different storage environment requirements. What adaptability does the warehouse tent's internal environmental control and detailed design require to meet diverse cargo storage needs?

To meet the storage needs of different cargoes, the warehouse tent must adapt through "environmental control modules" and "detailed customization." For goods requiring moisture protection (such as electronic components and precision instruments), a moisture-proof ventilation system must be installed, including industrial exhaust fans and dehumidifier connections, to maintain a relative humidity of ≤60%. Sealing should be done at the joints between the roof and the floor to prevent moisture from seeping in. Moisture-proof matting should be laid on the floor to isolate moisture from the ground. Some areas can also incorporate raised floors to further enhance moisture protection. For goods with poor weather resistance (such as textiles and paper packaging), the roof should be made of high-shading, UV-resistant fabric to prevent fading and degradation caused by direct sunlight. Insulation can be added to regulate the internal temperature to prevent high or low temperatures from affecting the goods. High-speed rolling doors can be installed to minimize the impact of external temperature and humidity on the internal environment when the door is opened and closed. For the storage of large and heavy equipment, a wide entrance (≥5 meters wide) should be designed to facilitate equipment entry and exit. Anti-slip steel plates should be installed on the floor to enhance friction and prevent equipment from sliding. Reinforced anchors can be installed at the bottom of the frame to enhance overall stability and prevent vibration caused by equipment handling from causing the tent to shift. Targeted designs can be used to meet diverse storage needs.

4.The Warehouse Tent needs to meet the requirements of "quick setup and disassembly." What features are required for its installation method and construction team configuration to enable the rapid deployment of large-scale warehouses?

To achieve rapid deployment, the Warehouse Tent's installation method must be designed around "modular construction" and "efficient collaboration." The installation method utilizes a "factory pre-assembly + on-site assembly" model: frame components are prefabricated into standardized modules at the factory and quickly connected via bolts or snaps, eliminating the need for on-site welding. The canopy fabric is cut to size and pre-sewn at the factory; on-site, it simply needs to be unfolded and secured to the frame, significantly reducing on-site construction time. For larger-span designs, a "segmented construction" method can be used: first constructing the two side frames, then installing the center beams, and finally adding the canopy, improving construction efficiency. Regarding construction team configuration, a "specialized, fast-track construction team" should be established. Team members should have clear divisions of labor (e.g., frame team, canopy team, and fixing team) and be familiar with the modular installation process. A team of 5-10 people can complete a warehouse tent under 1,000 square meters in one day. Specialized construction equipment (e.g., small cranes and electric wrenches) should be provided to assist with heavy frame installation, reducing labor consumption. A detailed site plan should be provided before construction to clearly define the frame location and fixing point distribution. This will prevent on-site adjustments that could delay construction and ensure the completion of large-scale deployments within a short period of time.

5. Warehouse tents are often used outdoors for long periods of time and must withstand severe weather conditions such as heavy rain, strong winds, high temperatures, and snow. What enhancements should be made to their protective design to ensure the safety of the warehouse structure and the cargo inside?

Harsh weather protection requires comprehensive enhancements tailored to specific risks. For rain protection, the canopy utilizes high-density waterproof fabric and heat-sealed technology, with a waterproof rating of ≥2000mmH₂O, ensuring no leakage in heavy rain. The canopy features a steep double-slope design with a slope of ≥15° to accelerate rainwater runoff and prevent water accumulation on the top. A rain skirt ≥30cm high is installed around the canopy edge to prevent rainwater from seeping through cracks in the ground. Drainage trenches are dug around the tent to direct rainwater away from the tent foundation, preventing ground water from soaking the frame. For wind protection, the frame utilizes a triangular stabilization structure with a main frame pipe diameter of ≥100mm to enhance wind resistance, capable of withstanding winds of force 8-10. The frame bottom is secured with a dual "ground-buried" system and counterweights, buried at a depth of ≥50cm. The counterweight weight is tailored to the tent's area (e.g., ≥10kg per square meter). Wind rope anchor points are located around the tent, equipped with high-strength wind ropes connected to remote anchors to create diagonal tension and mitigate lateral impact from strong winds. To protect against high temperatures and snow accumulation, a "sunshade and insulation layer" should be installed on the roof in hot weather to reduce the internal temperature. In snowy weather, a "snow melting system interface" should be installed on the roof, which can be connected to a hot air blower or snow melting belt to quickly melt the snow on the top. The frame should also be reinforced to withstand the load, and the spacing between crossbars should be increased to 1-1.5 meters to distribute the pressure of snow accumulation and prevent excessive snow from collapsing the frame, thus fully ensuring the safety of the structure and cargo.

6. The warehouse tent needs to be used in conjunction with warehouse equipment (such as forklifts, racks, and dehumidifiers). What "equipment coordination interfaces" should be reserved in the design to ensure efficient interaction with warehouse equipment?

To achieve coordination with warehouse equipment, the warehouse tent needs to reserve "spatial interfaces" and "functional interfaces." Regarding the spatial interface, the tent entrance must be designed with an adjustable-height roller shutter door, adjustable from 2.5 to 4 meters in height and ≥5 meters in width, to facilitate the entry and exit of large equipment such as forklifts and stackers. Internally, "shelf anchor points" are provided, with bolt holes in the ground or frame to directly secure heavy shelves and prevent them from shifting. Some models can feature an "emergency access door" ≥1.2 meters wide on the side to facilitate the passage of personnel and small equipment without interfering with the operation of equipment at the main entrance. Regarding the functional interface, the inner wall of the tent must be equipped with an industrial outlet (e.g., 380V, 220V) to power dehumidifiers, lighting, and forklift charging stations. A ventilation equipment installation port is provided on the top to directly install industrial exhaust fans or ventilation ducts to regulate the internal environment. The floor should be paved with anti-static flooring or wear-resistant matting with a non-slip surface treatment to accommodate forklift operation and cargo handling. This interface design ensures seamless coordination between equipment and the tent, improving storage efficiency.

7.In the production and supply of warehouse tents, what advantages does Yangzhou Mailenda Outdoor Products Co., Ltd. have to ensure the product's "storage adaptability" and "reliability"?

As a company with over 20 years of experience in the outdoor products industry, Yangzhou Mailenda Outdoor Products Co., Ltd. boasts numerous advantages in the production and supply of warehouse tents. On the production side, the company is familiar with the properties of core materials such as high-strength steel and waterproof-coated fabrics, enabling it to select appropriate materials based on storage needs. For example, thickened galvanized steel pipe frames are used for heavy cargo storage, while high-density waterproof fabrics are used for moisture-proofing. Advanced equipment such as automatic cutting machines, CNC bending machines, and hot air seam sealing machines ensure frame machining accuracy (error ≤ 1mm) and canopy seam sealing quality, ensuring structural stability and waterproof performance. Furthermore, customized designs such as moisture-proof layers, thermal insulation layers, and double-layer storage structures can be provided to enhance storage adaptability, depending on the type of goods being stored. In terms of quality control, a strict factory inspection process is in place, including load-bearing tests on the frame (simulating a 50kg load per square meter), waterproofing tests on the canopy (24-hour hydrostatic pressure testing), and wind resistance tests on the overall structure (simulating force 10 winds) to ensure the product meets the requirements of long-term outdoor use. Salt spray testing is also performed on the steel to verify its rust resistance, and abrasion testing is performed on the fabric to ensure long-term wear resistance. On the supply side, with two production bases and an annual production capacity of over 120,000 outdoor products, we can quickly respond to orders for large-span and large-area warehouse tents, supporting both batch and customized production. Equipped with a professional construction team, we provide a full-process service from "design, production, installation, and after-sales service" to ensure a seamless transition from product to use, providing reliable warehouse tent solutions for logistics transit, emergency warehousing, and other scenarios.

English

English 中文简体

中文简体 Español

Español 日本語

日本語 русский

русский عربى

عربى