-

Folding Aluminum Field Cot

Folding Aluminum Field CotMetal Bunk Beds & Field Bed

-

Heavy Duty Steel Field Cot

Heavy Duty Steel Field CotMetal Bunk Beds & Field Bed

-

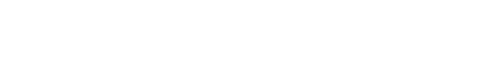

4x5m Reinforced Flexible Plastic Tarpaulins for Temporary Shelter

4x5m Reinforced Flexible Plastic Tarpaulins for Temporary ShelterPlastic Tarpaulin

-

4x6m Plastic Sheeting Emergency Tarpaulin

4x6m Plastic Sheeting Emergency TarpaulinPlastic Tarpaulin

-

4x50m Woven HDPE Black Plastic Tarpaulin

4x50m Woven HDPE Black Plastic TarpaulinPlastic Tarpaulin

-

4x60m Extra Large Plastic Tarpaulin Waterproof Cover Sheet

4x60m Extra Large Plastic Tarpaulin Waterproof Cover SheetPlastic Tarpaulin

-

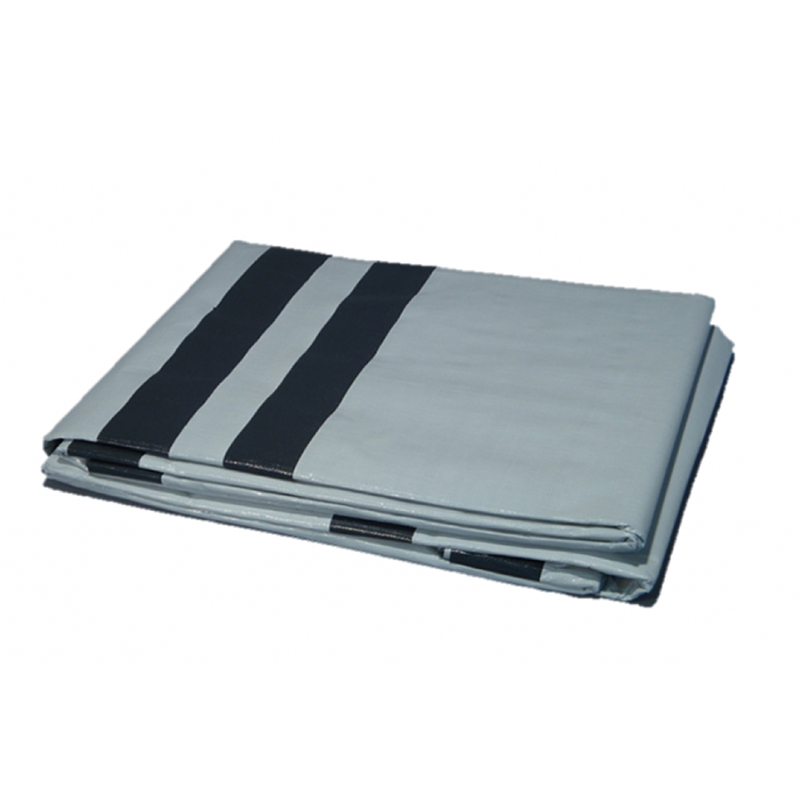

UNHCR Standard 1 Person Synthetic Sleep Mat

UNHCR Standard 1 Person Synthetic Sleep MatSleeping Mat

-

Multipurpose Portable Foam Sleeping Mat

Multipurpose Portable Foam Sleeping MatSleeping Mat

-

Low Thermal Knitted Fleece Blanket

Low Thermal Knitted Fleece BlanketThermal Synthetic Blankets

-

ICRC/IFRC Standard Medium Thermal Fleece Blanket

ICRC/IFRC Standard Medium Thermal Fleece BlanketThermal Synthetic Blankets

-

ICRC/IFRC/UNHCR Standard High Thermal Polyfill Blanket

ICRC/IFRC/UNHCR Standard High Thermal Polyfill BlanketThermal Synthetic Blankets

Core Relief Items Manufacturers

Products & Solutions

CONTACT US

-

+86 15695147631

-

-

No.9 Kangmin Road, Automobile industry Park, Yizheng City, Jiangsu Province, China

Core Relief Items kits include essential household items such as mattresses, blankets, plastic sheets, containers for water, cooking utensils and hygiene kits. Aim to improve the sustainability of our end-to-end supply chain for core relief items, reducing carbon emissions and using more recycled materials, where possible.

-

In the immediate aftermath of a natural disaster or humanitarian crisis, the first 60 minutes—often called the "Golden Hour"—are critical for establishing medical and logistical hubs. The Rapid Inflatable Relief Emergency Tent is engineered specifically for these high-pressure s...

READ MORE -

In the world of temporary structures, the Inflatable Tent represents a paradigm shift in deployment speed and structural resilience. By replacing traditional heavy metal or fiberglass poles with high-pressure "AirBeams," these structures can be erected in a fraction of the time ...

READ MORE -

For commercial growers and serious horticulturists, the decision to invest in a Greenhouse or a Polytunnel is a pivotal choice that dictates the operational success of a farm. While both structures aim to extend the growing season and protect crops from the elements, they utiliz...

READ MORE

1. What is the core definition of Core Relief Items? What categories do they typically include? How do we define "core" items to ensure that critical needs are prioritized during disaster relief?

Core Relief Items are essential supplies for the basic survival, daily necessities, and emergency relief of affected individuals in emergencies such as natural disasters and public emergencies. Their "core" status is primarily defined by three key criteria: urgency of need, widespread coverage, and irreplaceability. Common categories include: First, "survival supplies," such as disaster relief tents (temporary shelters), sleeping bags, moisture-proof mats (for accommodation), compressed biscuits, drinking water, and emergency food (for food); Second, "medical emergency supplies," such as first aid kits (including bandages, disinfectant, etc.), common medicines (cold medicine, anti-inflammatory drugs), and temporary medical tents (for setting up temporary medical centers); Third, "basic living supplies," such as emergency flashlights and power banks (for lighting and communication), waterproof raincoats, and warm clothing (for dealing with inclement weather); and Fourth, "rescue tools," such as engineering shovels, demolition tools, and fire extinguishers (for assisting in rescue operations). These supplies are directly related to the safety and basic needs of disaster victims and are difficult to replace with other supplies. Therefore, they must be prioritized in the stockpiling and allocation of disaster relief supplies.

2. how does the demand for Core Relief Items differ across different disaster types (e.g., earthquakes, floods, typhoons, and droughts)? How should targeted stockpiling be implemented to avoid misallocation of supplies?

Due to the varying environmental characteristics and damage patterns of different disasters, the demand for Core Relief Items varies significantly. Earthquake disasters are accompanied by collapsed houses and blocked roads, so priority should be given to stockpiling "temporary shelter and rescue tools" supplies, such as earthquake-resistant disaster relief tents (to withstand aftershocks), demolition tools (to rescue trapped people), and emergency food (to ensure food when roads are blocked). Tents must be easy to set up and adapt to complex terrain. Flood disasters often result in trapped people and humid environments, so priority should be given to stockpiling "waterproof and floating" supplies, such as waterproof disaster relief tents (to prevent rainwater from seeping in), life jackets, assault boats (to transfer trapped people), and moisture-proof sleeping bags (to prevent illness from moisture). At the same time, drinking water purification equipment should be added to deal with water source pollution. Typhoon disasters are characterized by strong winds and heavy rainfall, so emphasis should be placed on "wind and rain protection and emergency lighting" supplies, such as disaster relief tents with a wind resistance level of ≥8, reinforced ground nails (to prevent tents from being blown down), emergency flashlights, and spare batteries (to deal with power outages). Drought disasters mainly affect water sources and food, so priority should be given to stockpiling "drinking water and drought-resistant supplies", such as bottled water, large water storage tanks, drought-resistant seeds, and irrigation equipment. By categorizing reserves by disaster type, we can avoid mismatches such as stockpiling large quantities of life jackets for earthquakes or emergency tools for droughts.

3. Core Relief Items must meet the needs of "emergency deployment." What characteristics must their production, storage, and transportation possess to ensure rapid delivery to disaster areas after a disaster strikes?

To achieve emergency deployment, Core Relief Items must establish an efficient system across three key areas: production response, storage layout, and transportation adaptation. The production process needs to have "rapid conversion and scale-up capabilities": production companies need to reserve emergency production lines. For example, disaster relief tent production companies need to be equipped with automated cutting and welding equipment, and can start production within 24 hours after receiving an order. They also need to have a daily production capacity of more than 1,000 tents. Yangzhou Mailenda Outdoor Products Co., Ltd., as a company with more than 20 years of experience in outdoor product production, relies on automatic cutting machines, hot air seam sealing machines and other advanced equipment and an annual production capacity of more than 120,000 tents of various types. It can quickly respond to the urgent production needs of disaster relief tents; the reserve link needs to adopt "distributed reserves": regional reserve warehouses should be established in disaster-prone areas (such as earthquake zones and coastal typhoon areas) to shorten the distance for material allocation. At the same time, reserve materials need to be packaged according to the "minimum packaging unit" (such as disaster relief tents are individually packaged at "1 tent/bag") to facilitate quick inventory and handling; the transportation link needs to have "Multimodal Adaptability": Material packaging must be waterproof and wear-resistant, suitable for various modes of transport, including trucks, helicopters, and ships. For example, disaster relief tents should be foldable to a volume of ≤0.5m³ to facilitate helicopter airdrops. Clear labeling of material category and specifications (e.g., "Earthquake Relief Tent - 2-Person") is also required to facilitate quick identification and sorting during transportation.

4.Core Relief Items must meet material selection and quality standards to ensure durability and safety in the complex operating environments of disaster areas (e.g., high temperatures, low temperatures, high humidity, and high dust levels).

The complex environment of disaster areas places stringent demands on the materials and quality of Core Relief Items, necessitating the establishment of clear standards for durability, adaptability, and safety. Material selection requires specific optimization based on environmental characteristics. For example, disaster relief tents used in high-temperature areas should be made of UV-resistant fabric (UPF 50+) to prevent degradation caused by excessive sunlight. Sleeping bags used in low-temperature areas should be made of down or thickened fleece to ensure warmth at temperatures ≤ -10°C. Moisture-proof mats used in high-humidity environments should be made of waterproof PVC to prevent moisture and mold. Emergency food in dusty areas should be packaged in sealed aluminum foil to prevent dust contamination. Quality standards must meet specific standards, including key indicators such as breaking strength ≥ 300N, hydrostatic pressure ≥ 1500mmH₂O, and flame retardancy (afterburn time ≤ 5s). Emergency food must comply with food safety regulations and have a shelf life of ≥ 6 months. Medications in first aid kits must be up to date and not deteriorating. Furthermore, all supplies must undergo rigorous factory inspection, with a sampling rate of at least 5% per batch to ensure compliance with quality standards.

5."Temporary Shelter" items in the Core Relief Items (such as disaster relief tents and temporary housing) must be designed to balance "quick setup" with "comfort and safety." How can these two requirements be balanced?

"Temporary Shelter" items must achieve a balance between "quick setup" and "comfort and safety" through "structural optimization," "functional simplification," and "detailed protection." For quick setup, a "modular and pre-assembled design" is employed. For example, disaster relief tents utilize quick-open brackets, requiring no complex tools and can be erected by two to three people in 30 minutes. Temporary housing utilizes modular panels with standardized components and snap-on connections, reducing on-site assembly time. Additionally, illustrated construction guides highlight key steps and common pitfalls, making them easy to use even for non-professionals. Regarding comfort and safety, the structural design must ensure a basic living experience. Disaster relief tents must be 1.5 meters or higher to allow adults to sit or stand freely, and must have at least two ventilation windows to prevent stuffiness. Temporary housing utilizes fire-resistant panels and a simple ventilation system to prevent carbon monoxide accumulation. Regarding protective details, the tent frame features rounded corners to prevent injuries from collisions caused by sharp edges. Moisture-proof mats are laid on the floors of the resettlement housing to prevent moisture from entering. Both structures must provide basic wind resistance (≥ Force 6 for tents and ≥ Force 8 for resettlement housing) to ensure safety. By balancing the dual needs of "simplifying setup steps" while retaining basic comfort and safety features, Yangzhou Mailenda Outdoor Products Co., Ltd. incorporates pre-assembled brackets and ventilation windows in its disaster relief tent design, balancing setup efficiency with a comfortable living experience.

6.the supply of Core Relief Items must cover multiple channels, including procurement by humanitarian organizations and corporate donations. What are the common and differentiated requirements for material specifications and certification across these channels?

Different supply channels have both common basic standards and differentiated requirements for Core Relief Items. Common requirements focus on "quality and compliance": All channels require supplies to have quality inspection reports and clear packaging labeling (including manufacturer, specifications, production date, expiration date, and other information). For food and pharmaceutical supplies, relevant business qualifications are required to ensure compliance. Differentiated requirements primarily focus on "customization and additional services": Humanitarian organizations (such as UN agencies) must ensure procurement complies with international standards (e.g., tents must comply with ISO standards) and provide multilingual instruction manuals (at least in English and the local language). Some organizations also require on-site installation training. Corporate donation channels offer more flexibility and can customize specifications based on the specific needs of the disaster area (e.g., small sleeping bags for children). However, they must ensure quality standards and provide a list of donated supplies and a quality assurance statement. Regardless of the channel, companies must have a comprehensive supply chain and quality control system. Yangzhou Mailenda Outdoor Products Co., Ltd., with its extensive international bidding experience and multilingual service capabilities, can adapt to the needs of different channels.

7.how are Core Relief Items recycled, disinfected, reused, or destroyed after use in a disaster to achieve resource conservation and environmental friendliness?

To achieve resource conservation and environmental friendliness, Core Relief Items must establish a full lifecycle management system encompassing "classification and tiered utilization." Recycling requires "classified collection and evaluation": Professional organizations will categorize materials into reusable items (e.g., disaster relief tents, sleeping bags), those requiring disinfection (e.g., medical first aid kit casings, temporary medical tents), and those unusable (e.g., expired food, contaminated medicines). The integrity of the materials will also be assessed. For example, if a disaster relief tent is damaged ≤10%, it can be repaired and reused; however, if it is severely damaged, it must be disassembled and recycled. Disinfection requires targeted treatment: Textile materials (e.g., sleeping bags, tent fabrics) should be disinfected with high-temperature disinfection (washing in hot water ≥60°C) or ultraviolet light to kill bacteria and viruses; metal materials (e.g., rescue tools, tent frames) should be disinfected with alcohol wipes or sprays of disinfectant; and the outer casings of medical supplies should be disinfected by soaking in a chlorine-containing disinfectant, with contaminated internal components destroyed separately. Regarding secondary utilization, materials in good condition can be stored in a reserve for use in the next disaster relief effort. Minor damage can be repaired and donated to areas in need (e.g., disaster relief tents can be repaired and used as temporary storage in rural areas). Materials that cannot be repaired can be disassembled and recycled for raw materials, such as tent fabrics being recycled into recycled plastic, or metal frames being melted and reprocessed. Destruction requires environmentally friendly disposal: expired food and contaminated pharmaceuticals must be disposed of harmlessly (e.g., incinerated or buried) in accordance with environmental regulations to avoid environmental pollution. Through comprehensive process management, resource utilization can be maximized and waste reduced.

English

English 中文简体

中文简体 Español

Español 日本語

日本語 русский

русский عربى

عربى